manufacturing of geotextile

Key Word:

Geocell, Geogrid, Geotextile, Grass Grid, Geomembrane, Geotube, Composites, Geomat, Geobag

Category:

隐藏域元素占位

- Product Description

-

- Commodity name: manufacturing of geotextile

- 列表页概要: Geotextiles are essential materials in various engineering and construction projects. The manufacturing of geotextiles is a sophisticated process.

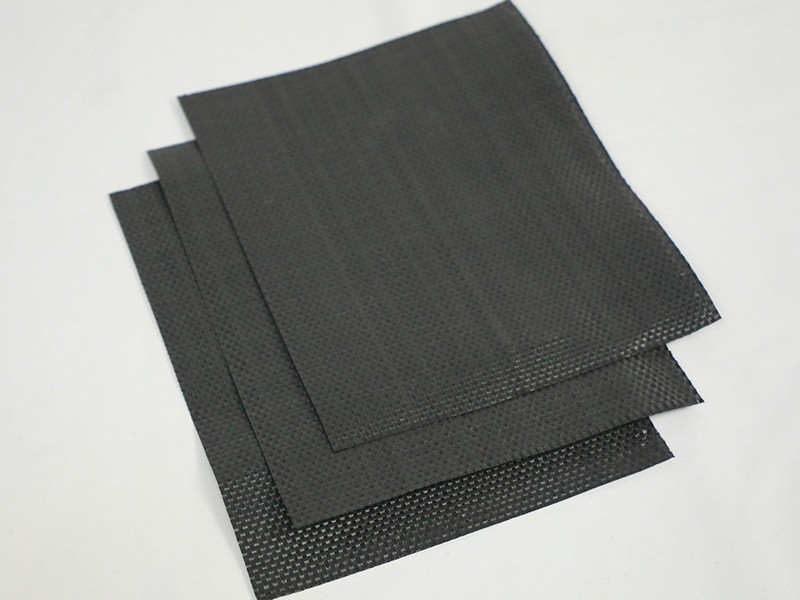

Geotextiles are essential materials in various engineering and construction projects. The manufacturing of geotextiles is a sophisticated process.

manufacturing of geotextile

Geotextiles are essential materials in various engineering and construction projects. The manufacturing of geotextiles is a sophisticated process.

The first step in the manufacturing of geotextile is the selection of appropriate raw materials. High-quality polymers, such as polypropylene or polyester, are commonly used. These materials are melted and extruded to form continuous filaments.

The filaments are then woven or non-woven to create the fabric structure of the geotextile. Woven geotextiles offer high strength and stability, while non-woven geotextiles provide better filtration and drainage properties.

During the manufacturing process, various techniques are employed to enhance the performance of the geotextile. It may be treated with chemicals to improve its resistance to UV rays, chemicals, and abrasion. Surface treatments can also be applied to modify its permeability or frictional characteristics.

The manufactured geotextiles find extensive applications. They are used in road construction to reinforce the pavement and prevent rutting. In landfill projects, they act as a barrier to separate waste and prevent leachate migration. Geotextiles also play a crucial role in coastal engineering, providing erosion control and shoreline protection.

Moreover, continuous innovation in manufacturing technology leads to the development of geotextiles with enhanced properties. New materials and processes are being explored to meet the increasing demands of complex engineering projects.

In conclusion, the manufacturing of geotextile is a vital industry that produces materials that are indispensable in modern construction and infrastructure development. Their diverse applications and evolving technology ensure their continued importance in the engineering field.

Technical standard

Product Specifications and Performance Parameters

serial number

project

index

20-15

30-22

40-28

50-35

60-42

80-56

100-70

1

Longitudinal breaking strength, KN/M≥

20

30

40

50

60

80

100

2

Weft breaking strength, KN/M≥

15

twenty two

28

35

42

50

70

3

Warp elongation at break, ≤

28

4

Trapezoidal tear strength (longitudinal) KN≥

0.3

0.45

0.5

0.6

0.75

1.0

1.2

5

Bursting strength, KN

1.6

2.4

3.2

4.0

4.8

6.0

7.5

6

Bursting strength, KN

Vertical permeability coefficient, cm/s

10-1~10-4

7

Equivalent aperture ⊙95, mm

0.08~0.5

8

Mass per unit area

120

160

200

240

280

340

400

Allowable deviation, %

±10

9

Engage in strong UV protection

According to design or contract requirements

Related Products

Inquiry