Biaxial Stretch Plastic Geogrid,biaxial integral geogrid products

Tensile Strength:15-50KN

Roll Size:3.95*100m,2*50m,as request

Key Word:

Geocell, Geogrid, Geotextile, Grass Grid, Geomembrane, Geotube, Composites, Geomat, Geobag

Category:

隐藏域元素占位

- Product Description

-

- Commodity name: Biaxial Stretch Plastic Geogrid,biaxial integral geogrid products

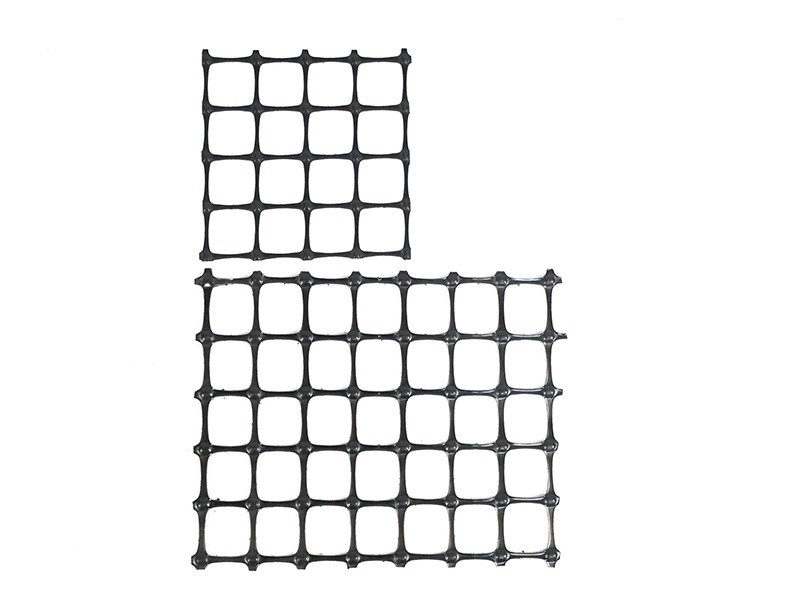

- 列表页概要: The appearance of the biaxially stretched plastic geogrid is similar to a square network structure. Extruded into a plate by hot melting, punched, heated, and stretched vertically and horizontally.

The appearance of the biaxial stretch plastic geogrid is similar to a square network structure. Extruded into a plate by hot melting, punched, heated, and stretched vertically and horizontally.The manufacturing process of biaxial integral geogrid products involves extruding and stretching polymer sheets to form a grid-like pattern with equal strength in both longitudinal and transverse directions. <BR> Tensile Strength:15-50KN<BR> Roll Size:3.95*100m,2*50m,as request

Biaxial integral geogrid products

Product description of biaxial stretch plastic geogrid:

The appearance of the biaxially stretched plastic geogrid is similar to a square network structure. It is made of polypropylene or high-density polyethylene as the main raw material, extruded into a plate by hot melting, punched, heated, and stretched vertically and horizontally. . The material has great tensile strength in the longitudinal and transverse directions, and is widely used in soft ground reinforcement.

represent a significant advancement in geosynthetic engineering, designed to enhance soil stabilization and reinforcement in civil engineering projects. These geogrids are characterized by their multidirectional tensile strength, which provides superior load-bearing capacity in both primary and secondary directions. Manufactured using high-density polyethylene (HDPE) or other polymers, they feature a uniform grid structure that effectively distributes tensile forces across soil layers, thereby improving structural integrity and preventing soil erosion. Biaxial integral geogrids are widely used in road construction, embankment stabilization, and retaining wall applications to prolong infrastructure lifespan and reduce maintenance costs.

represent a significant advancement in geosynthetic engineering, designed to enhance soil stabilization and reinforcement in civil engineering projects. These geogrids are characterized by their multidirectional tensile strength, which provides superior load-bearing capacity in both primary and secondary directions. Manufactured using high-density polyethylene (HDPE) or other polymers, they feature a uniform grid structure that effectively distributes tensile forces across soil layers, thereby improving structural integrity and preventing soil erosion. Biaxial integral geogrids are widely used in road construction, embankment stabilization, and retaining wall applications to prolong infrastructure lifespan and reduce maintenance costs.The manufacturing process of biaxial integral geogrid products involves extruding and stretching polymer sheets to form a grid-like pattern with equal strength in both longitudinal and transverse directions. This biaxial orientation enhances the geogrid's ability to withstand tensile forces from various angles, accommodating complex loading conditions in civil engineering projects. Advanced welding technologies ensure seamless junctions within the grid structure, eliminating potential weak points and ensuring uniform strength distribution across the entire geogrid surface. These products are available in various strengths and aperture sizes to suit specific project requirements, offering engineers versatility in addressing soil reinforcement challenges effectively.

Application of biaxial integral geogrid products contributes to sustainable development goals by improving the performance and longevity of civil infrastructure. By reinforcing soil layers, these geogrids reduce the need for excessive excavation and the use of traditional fill materials, minimizing environmental impact and preserving natural resources. Their high durability and resistance to chemical degradation make them suitable for diverse environmental conditions, including harsh climates and aggressive soil compositions. Beyond enhancing structural stability, biaxial integral geogrid products facilitate cost-effective construction practices by optimizing material usage and reducing maintenance expenses over the project lifecycle.

Features of biaxial stretch plastic geogrid:

High tensile strength, high plane torsional modulus, good creep performance and stable chemical properties;

High resistance to mechanical damage and durability, large friction coefficient with sand and gravel;

It can improve the bearing capacity of the foundation (generally it can be increased by more than 40%), and increase the diffusion angle (increase from 38 degrees to 50 degrees on average);

Under the same load and shaft times, the same effect can be achieved, and the thickness of the filling can be reduced by 30%-40%. When the geogrid is used for reinforcement, the subgrade of the same thickness can bear more than 3.5 times.

Application range of biaxial stretch plastic geogrid:

1. It is suitable for roadbed enhancement and road surface enhancement of various roads, railways, and airports;

2. It is suitable for foundation reinforcement of permanent loads such as large parking lots and wharf yards;

3. Suitable for slope protection of railways and highways;

4. Applicable culvert reinforcement;

5. It is suitable for the secondary reinforcement of the soil slope reinforced by unidirectional tensile geogrid, further strengthening the soil slope and preventing soil erosion;

6. Mine and tunnel reinforcement.

Technical standard of biaxial stretch plastic geogrid:

Biaxially stretched polypropylene geogrid specifications and performance parameters GB/T17689-2008

product specification

Longitudinal/transverse tensile strength/(kN/m)

Tensile strength at 2% elongation/(kN/m)

Tensile strength at 5% longitudinal/transverse elongation/(kN/m)

Longitudinal/transverse nominal elongation/%

TGSG1515

≥15

≥5

≥7

≤15/13

TGSG2020

≥20

≥7

≥14

TGSG2525

≥25

≥9

≥17

TGSG3030

≥30

≥10.5

≥21

TGSG3535

≥35

≥12

≥24

TGSG4040

≥40

≥14

≥28

TGSG4545

≥45

≥16

≥32

TGSG5050

≥50

≥17.5

≥35

Related Products

Inquiry